Industrial water treatment professionals face significant challenges in maintaining water quality and meeting regulatory standards. Traditional methods often rely on chemical inputs as the primary oxidant for disinfection and treatment. However, concerns surrounding chemicals safety and environmental impact have prompted the search for alternative solutions. On-site generation of hydrogen peroxide (H2O2) has emerged as a game-changing technology, providing industrial water treatment professionals with a safe, efficient, and sustainable method of producing a green oxidant that eliminates the need for chemicals, enhances water treatment processes, and makes handling of dangerous chemicals a thing of the past.

Green Oxidant, Generated On-Site

Green Oxidant, Generated On-Site

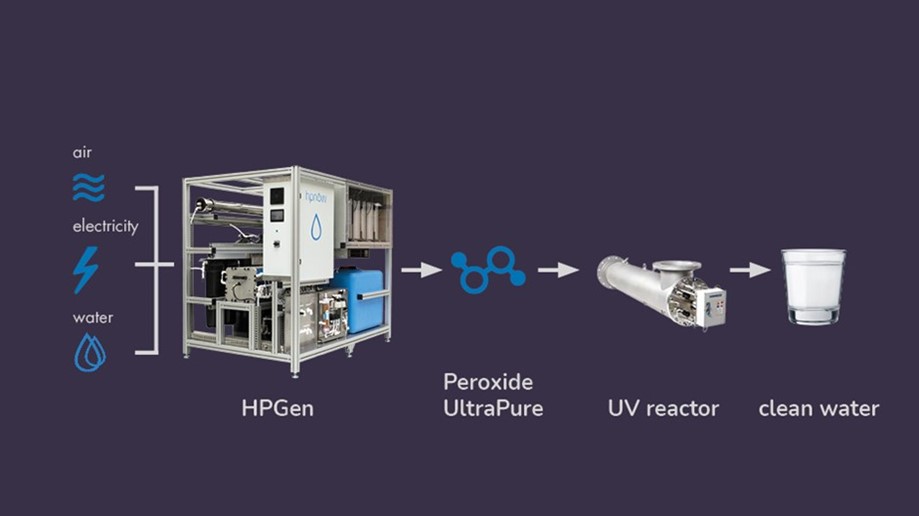

The development of on-site hydrogen peroxide generation technology presents a revolutionary solution in industrial water treatment. By eliminating the need for transportation, storage, and handling of hazardous chemicals, this method offers enhanced safety and convenience for water treatment professionals. On-site hydrogen peroxide generation employs an electrochemical process, utilizing water, air, and electricity to produce high-purity hydrogen peroxide, a green oxidant, directly at the treatment facility. After use, hydrogen peroxide becomes water and oxygen, leaving no residues behind. This technology, first commercialized by Danish company HPNow, offers five key benefits.

Benefit #1: Green Oxidant

Hydrogen peroxide generated on-site is a green oxidant that does not produce harmful disinfection byproducts, becoming water and oxygen after use. It offers a sustainable solution for water treatment, aligning with the growing demand for environmentally friendly practices and meeting regulatory standards for water quality. Because it is directly generated at the point of use, traditional supply chains, which are heavy on CO2 emissions, are bypassed altogether. The very high purity at which it is generated makes it intrinsically stable, with a storage life in the field of up to 6 weeks. This also means there are no stabilizers added, which increases compatibility with numerous processes.

Cooling water tower treatment is crucial for efficient operation of industrial facilities, but many existing methods rely on toxic chemicals that require storage and handling. HPNow’s groundbreaking solution offers a sustainable alternative. It generates a green oxidant called Peroxide UltraPure™ on-site using water, air, and electricity. To demonstrate its effectiveness, an HPNow system was installed in a struggling cooling tower with high bacteria levels that chlorine-based solutions were unable to contain. Following installation of the HPNow system, safe bacteria counts were measured in the treated water. The operation now benefits from a better sustainability profile, enhanced safety and no handling of chemicals, which makes it smoother to maintain.

Benefit #2: Chemical-input free Solution

The on-site generation of hydrogen peroxide eliminates the dependence on chemical oxidants. Hydrogen peroxide produced through this method serves as an effective alternative, delivering superior disinfection and oxidation capabilities without the transportation, handling and storage hazards associated with chemical-based solutions such as chlorine or bulk peroxide. Since no chemicals are required for the on-site generation of peroxide, this also secures the supply and protects the operations against supply chain disruptions and price increases.

Benefit #3: Enhanced Safety

Water treatment professionals can significantly enhance safety by avoiding the handling and storage of hazardous chemicals. On-site generation of hydrogen peroxide eliminates the risks associated with chemicals, ensuring a safer working environment for operators and reducing the potential for accidents and exposure incidents. Staff do not have to handle concentrated hazardous substances such as chlorine or highly concentrated hydrogen peroxide, contributing to a safer workplace.

Water treatment operations face the challenge of removing pollutants like pharmaceuticals and pesticides from water. Advanced oxidation processes (AOPs) play a crucial role in eliminating these harmful substances, preventing them from accumulating in drinking water. AOP combines hydrogen peroxide (H2O2) with either ultraviolet light or ozone to break down stubborn pollutants. HPNow’s HPGen technology offers a sustainable solution by producing 99.999% pure hydrogen peroxide on-site, using only air, electricity, and water. This chemical-input-free approach enhances safety, reduces carbon emissions, and ensures a stable supply of peroxide for AOP. Field tests conducted in collaboration with Xylem and Evonik demonstrated the successful integration of HPGen with a UV AOP solution, effectively degrading various emerging contaminants. The use of Peroxide UltraPure in combination with a UV reactor offers a green and efficient method to achieve clean water. To read the full case study, please visit this page.

Benefit #4: Cost-Effectiveness

On-site hydrogen peroxide generation reduces costs associated with chemical procurement, transportation, and storage. Water treatment professionals can produce the required amount of hydrogen peroxide as needed, eliminating the need for bulk purchases and reducing the risk of chemical degradation over time. With the HPNow system, the ongoing operational expenses associated with bulk chemicals are a thing of the past. The machine itself runs on ambient air, water, and electricity.

Benefit #5: Flexibility and Scalability

On-site generation systems for hydrogen peroxide are customizable and scalable to meet specific treatment requirements. The technology allows for efficient adjustments based on varying demand and water quality fluctuations, ensuring optimal performance in diverse industrial applications. Thanks to the ease of installation and the design of the HPNow machine, which was created with scalability in mind, the system can be used in a wide range of industrial water treatment applications of any size.

Conclusion

On-site generation of hydrogen peroxide represents a significant breakthrough in industrial water treatment. This patented technology enhances safety, meets regulatory requirements, and contributes to a greener approach to water treatment.

The on-site production of hydrogen peroxide, as enabled by the HPNow system, offers cost-effective advantages by reducing chemical procurement and storage expenses. With its flexibility and scalability, on-site hydrogen peroxide generation provides water treatment professionals with a sustainable and efficient solution for maintaining water quality. By embracing this technology, the future of industrial water treatment will be safer, more efficient, and environmentally conscious.